In the world of food formulation, few ingredients are as misunderstood as maltodextrin. Driven by the “clean label” movement, it’s often dismissed by marketing teams and consumers as a cheap “filler” or an unnecessary additive. For the food technologist, however, this perception overlooks a critical reality: maltodextrin is one of the most versatile and functional ingredients available.

This article provides a reality check, moving beyond the myths to explore the indispensable technical roles that highlight the true functionality of maltodextrin. It’s time to re-evaluate this ingredient not for what it isn’t, but for what it does.

More than a bulking agent: the role of DE

To understand the functionality of maltodextrin, one must first understand Dextrose Equivalent (DE). DE is a measure of the total percentage of reducing sugars, calculated on a dry basis. It essentially indicates how much the starch has been hydrolyzed. This value, which typically ranges from 3 to 20 for maltodextrin, directly dictates its properties:

- Low DE Maltodextrin (3-10): Less sweet, creates higher viscosity, has better film-forming properties, and is less hygroscopic (absorbs less moisture).

- High DE Maltodextrin (15-20): Slightly sweeter, lower viscosity, more hygroscopic, and has a higher browning potential (Maillard reaction).

Choosing the right DE is the first step in leveraging maltodextrin as a precise technical tool rather than a generic filler.

The invisible workhorse: maltodextrin as a carrier

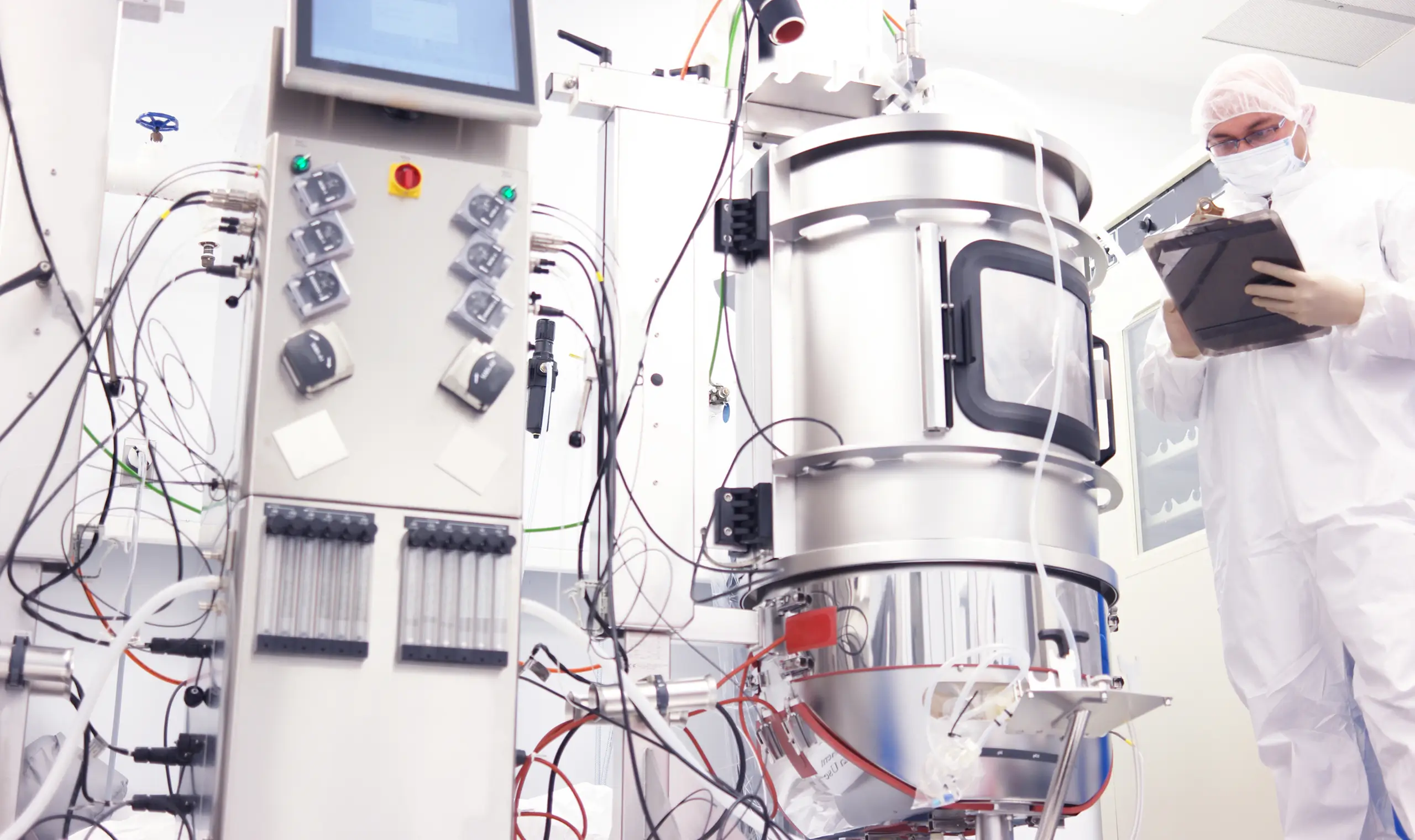

One of the most vital roles of maltodextrin is as a carrier agent in spray drying. Its ability to form a protective film and its neutral flavor profile make it the industry standard for converting liquids into powders.

This is a key aspect of the functionality of maltodextrin. It is used to encapsulate and stabilize:

- Flavors and essential oils: Protecting them from oxidation and degradation.

- Vitamins and sensitive active compounds: Ensuring their potency and shelf life.

- Fats and oils: Creating powdered fats used in bakery mixes, sauces, and infant formula.

Without maltodextrin, many of the powdered flavors, supplements, and ingredients we rely on would not be commercially viable.

Master of texture and mouthfeel

Maltodextrin is a master of controlling water and solids in a formula, which gives formulators precise control over the final product’s texture.

- In beverages: It adds body and mouthfeel without significant sweetness, improving the sensory experience of low-sugar drinks.

- In frozen desserts: A low DE maltodextrin inhibits ice crystal formation, resulting in a smoother, creamier texture in ice cream and sorbets.

- In sauces and dressings: It provides viscosity and cling, creating a more stable and appealing product.

A reality check on “clean label”

The pressure to remove maltodextrin from a label is a real challenge for formulators. However, replacing it often requires a complex blend of more expensive hydrocolloids, fibers, and sweeteners that may not replicate its performance.

The decision to use maltodextrin should be a technical one, based on its performance and cost-effectiveness. The true functionality of maltodextrin often provides a more stable, better-tasting, and more efficient solution than its “cleaner” alternatives.

At Nutri Partners, we supply a range of high-quality maltodextrins with varying DE values. We provide the technical data to help our partners make informed, pragmatic decisions based on science and functionality, not just marketing trends.